Industrial & Manufacturing Labels

For Enhanced Processes, Safety and Compliance, Efficiency, and Quality Control

Enhance Your Processes with Industrial and Manufacturing Custom Labels

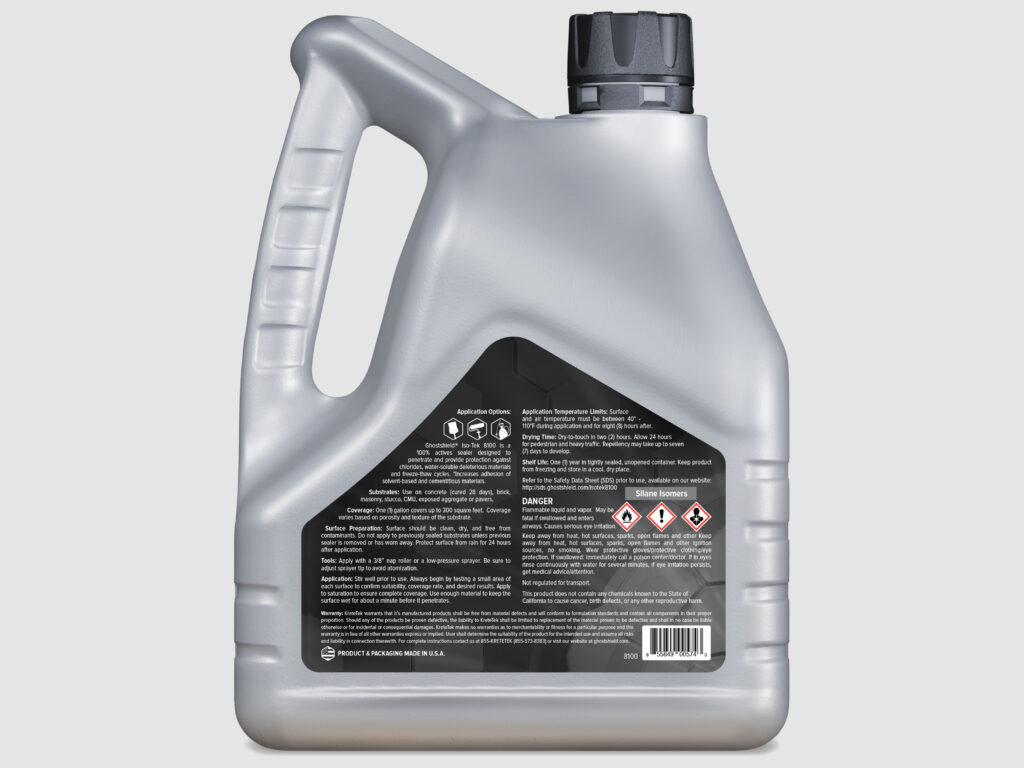

Product identification, safety warnings, instructions, regulatory compliance, and barcodes are just some of the uses and applications of industrial and manufacturing labels. Besides enhancing the shelf appeal of products, there are other requirements that these types of labels need to meet. Industrial and manufacturing labels need to be durable, withstanding harsh conditions, such as extreme temperatures, moisture, and chemicals. Another requirement is readability. The information on the label must be clear and easy to read. Thirdly, industrial and manufacturing labels must adhere securely to surfaces. Lastly, these types of labels need to comply with any applicable regulations.

Label Products for Industrial & Manufacturing

There are several things to consider when picking out a label product for industrial and manufacturing applications. Some factors include durability, readability, and functionality in diverse environments. Here are some popular options:

Paper Labels

While more durable materials like vinyl, polyester, and metal are often preferred for harsh environments, paper labels offer certain advantages. They can be easily printed using standard printers, making them convenient for small-scale operations. Paper labels are also a more cost-effective option, as they are generally more affordable than synthetic or metal labels.

Film Labels

Film labels, especially materials like polyester, polypropylene, or vinyl, offer several benefits. They offer a combination of durability, versatility, customizability, and readability. Film labels resist water, chemicals, abrasion, and extreme temperatures, making them suitable for a wide range of indoor and outdoor applications. These labels can be customized to specific sizes, shapes, and adhesive types, ensuring they meet unique requirements. Film labels also print with high-quality graphics and legible text, which enhances product identification and information clarity.

Cling Window Decals

Cling window decals can be a valuable tool in industrial and manufacturing settings. They can quickly and easily display safety messages, hazard warnings, or emergency procedures on windows or glass surfaces. Additionally, they can indicate temporary changes in layout, equipment placement, or workflow. Furthermore, cling window decals can promote company branding, product launches, or special offers. The key advantage of these decals is their ease of application and removal, making them a flexible solution for temporary or seasonal signage needs.

Durable Labels

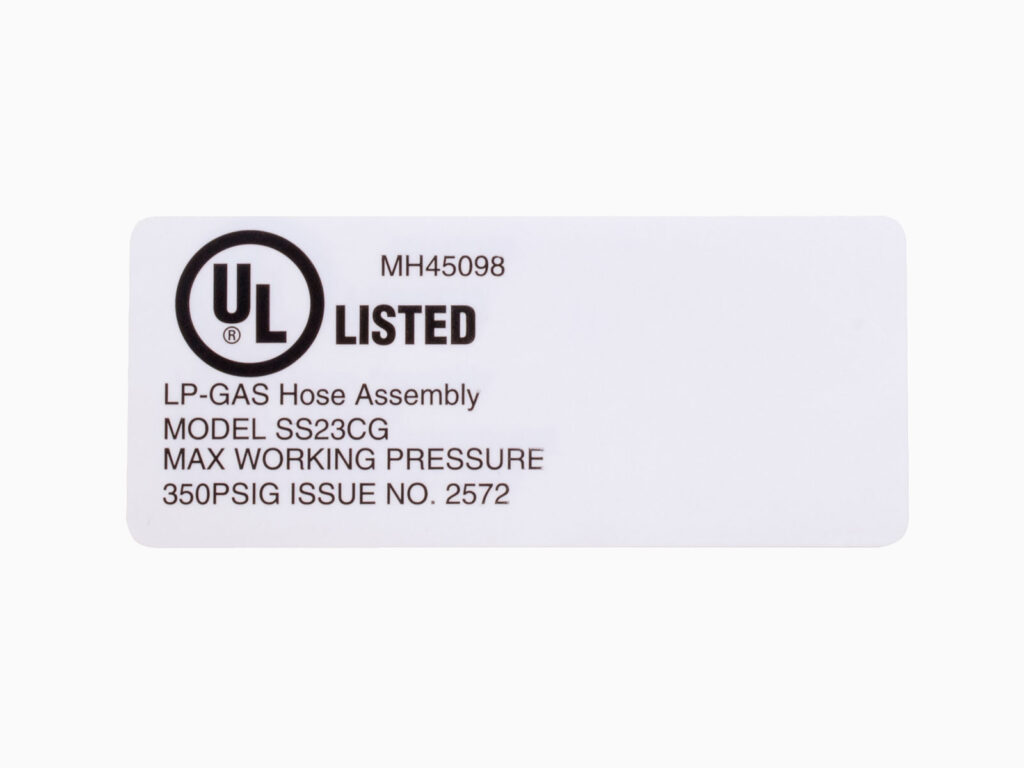

Durable labels are a top choice to use in industrial and manufacturing settings because they can withstand harsh conditions. They are essential for product identification, asset tracking, safety labeling, regulatory compliance, and logistics and shipping, ensuring products are properly identified, tracked, and protected throughout their lifecycle.

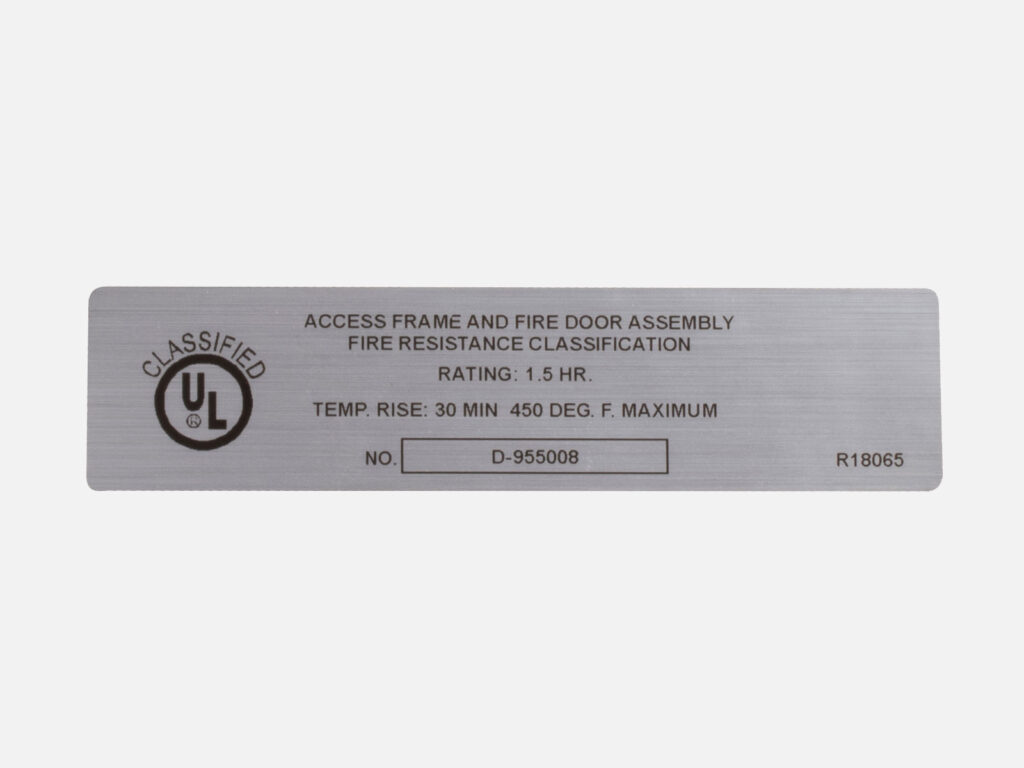

Nameplates

Nameplates are essential for providing clear and concise information, such as product identification, model numbers, serial numbers, and safety warnings. They are often made from durable materials like metal, plastic, or ceramic to withstand harsh environments. Use durable labels on equipment, machinery, control panels, and other industrial components.

Security and Brand Protection Labels

These labels are crucial for safeguarding a company’s brand reputation, preventing counterfeiting, ensuring product authenticity, thereby building customer trust and protecting revenue. Some common applications of security and brand protection labels used in industrial and manufacturing settings include product authentication to verify the genuineness of products and prevent counterfeit goods from entering the market, tamper evidence to detect unauthorized tampering and product alteration, tracking products though the supply chain to identify any security breaches, and finally for brand protection.

Double Sided Window Decals

These decals can display important safety information on both sides of windows or glass doors, ensuring visibility from both directions. Additionally, they make for directional signage to guide workers and visitors through facilities, particularly in complex layouts or during temporary reconfigurations. Furthermore, double-sided window decals can provide clear instructions for emergency procedures, visible from both inside and outside the building. By utilizing these versatile decals, businesses can enhance safety, efficiency, and overall communication within their industrial and manufacturing facilities.

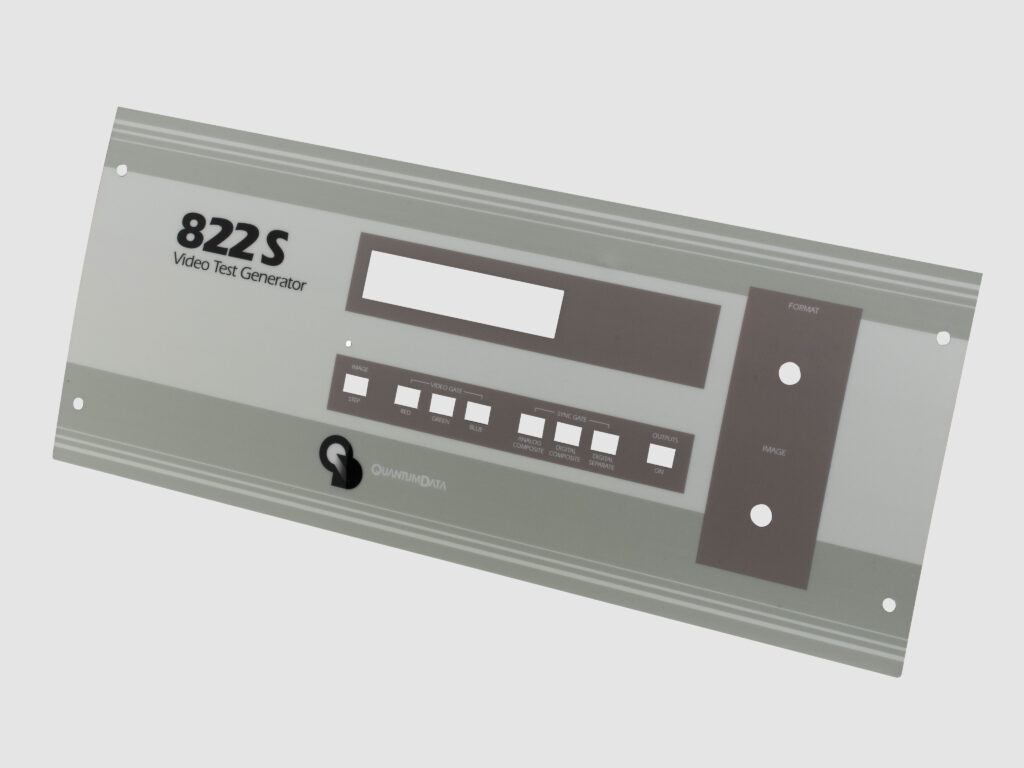

Graphic Overlays

You can frequently find graphic overlays in industrial and manufacturing settings since they provide clear and concise information, enhance user experience, and protect underlying components on equipment. Some examples are control panels, which provide clear labeling for buttons, switches, and displays; instrument panels including gauges, meters, and other critical information; membrane switches enabling touch-sensitive input and control; and finally, equipment housings which provide branding, safety warnings, and operating instructions. They are often made from durable materials like polycarbonate or polyester to withstand harsh environments, including exposure to chemicals, extreme temperatures, and physical impact.

Polycarbonate / Lexan Labels

Polycarbonate is a highly durable and versatile material that offers excellent resistance to impact, heat, and chemicals. These labels are ideal for applications that require long-lasting, high-performance labeling, such as equipment identification, safety signage, control panel labeling, and for outdoor applications. The durability and clarity of polycarbonate labels ensures that critical information remains legible and durable, even in the most demanding environments.

Thermal Transfer Labels

Thermal transfer labels are printed using a thermal transfer printer and a ribbon. This method allows for high-quality, durable prints that can withstand harsh conditions, such as extreme temperatures, moisture, and chemicals. They offer a high level of durability and print quality, making them ideal for a variety of applications such as product identification, asset tracking, shipping and logistics, inventory management, and finally, safety warnings.

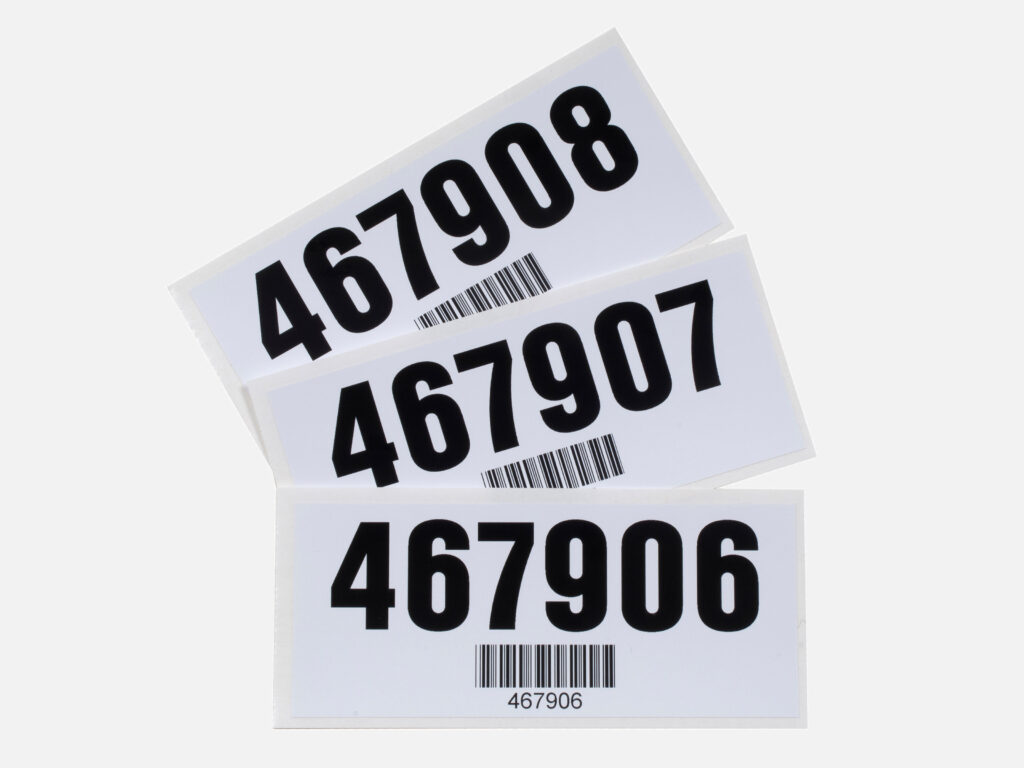

Variable Data Labels

Variable data labels allow for dynamic information to be printed on each label, making them highly versatile and adaptable to various needs in industrial and manufacturing settings. Manufacturers can improve efficiency, enhance product traceability, and ensure regulatory compliance. A couple of important applications of variable data labels are product serialization and batch and lot tracking. This allows for product traceability, verification of authenticity, and for identifying specific lots of products for quality control and recall purposes. Another advantage of variable data labels is the ability to use real-time data integration which ensures accurate and up-to-date information such as printing expiration dates and personalizing labels to specific customers.

Label Enhancements for Industrial & Manufacturing

Label enhancements for industrial and manufacturing labels have significantly evolved, driven by technological advancements and increasing industry demands. depending on your specifications and budget. Call Gallas today for more details.

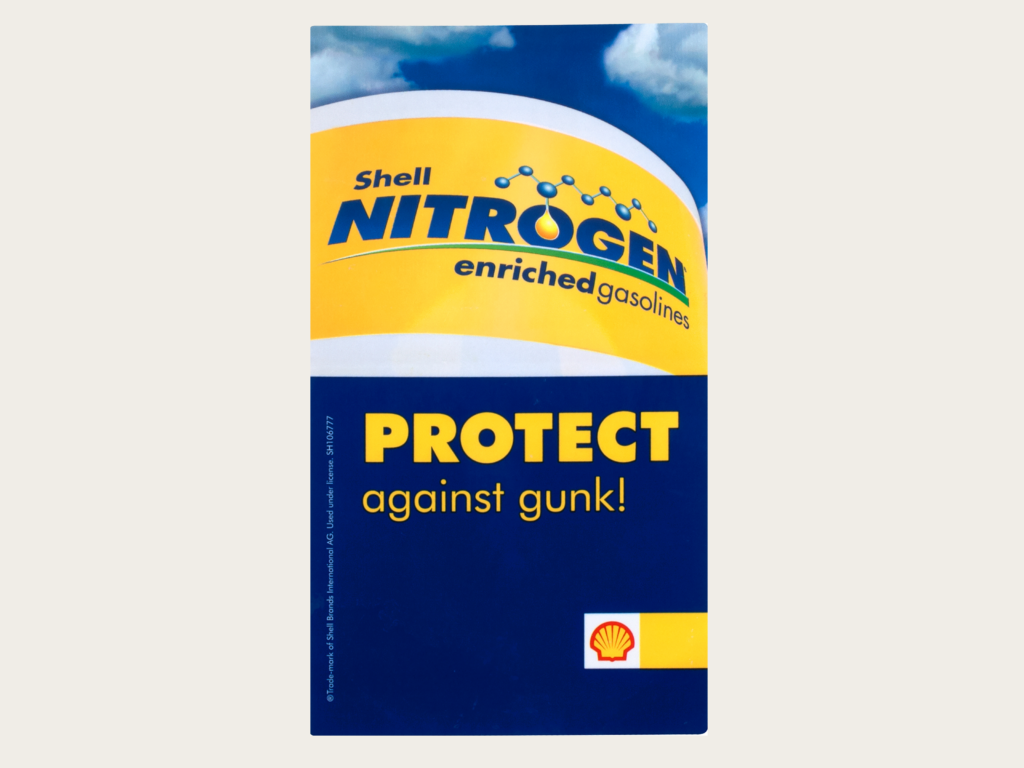

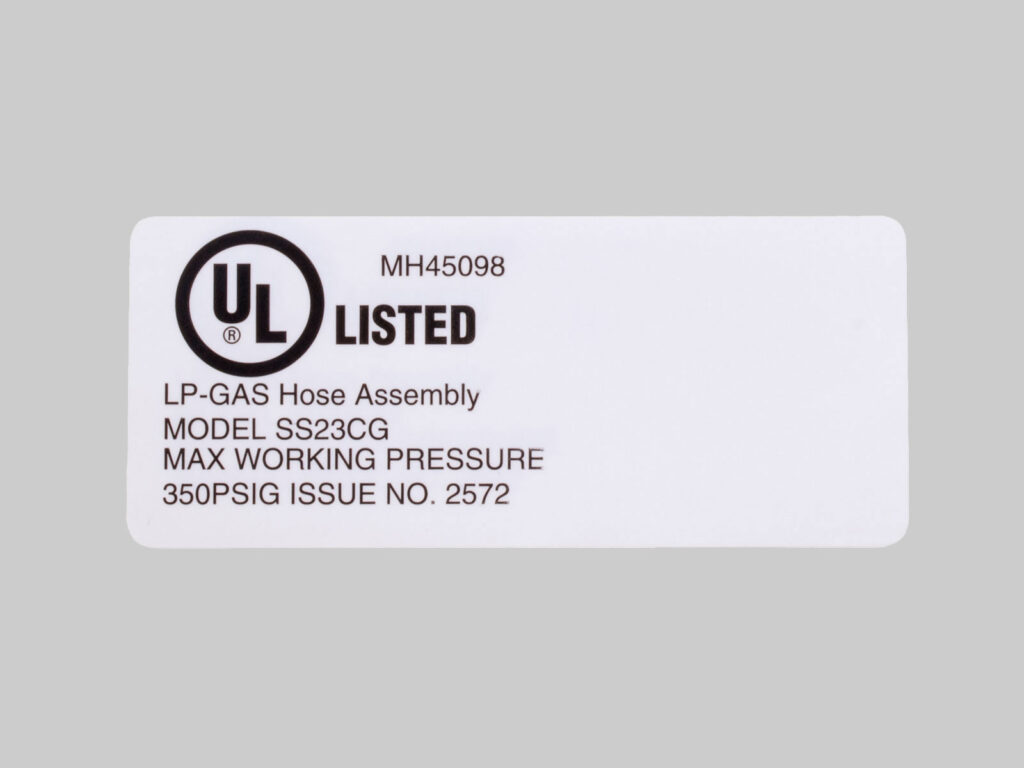

Our Work

Check out customer examples of industrial and manufacturing labels.

Tips on Choosing the Right Label Products & Enhancements for Industrial and Manufacturing Applications

Consider the following factors when selecting label product and enhancements for industrial and manufacturing applications:

Environmental Conditions

Consider what types of conditions your products will be under. Will there be extreme temperatures? High humidity or moisture? UV exposure through artificial light or direct sunlight? Or maybe chemical exposures? These factors can determine the label material and enhancements you will need.

Label Application Method

Will there be manual or automated label application? If there will be manual application, consider if there will be easy application of the labels and the need for operator training. For automated application, the label must be compatible with the machinery.

Regulatory Compliance

Ensure that the labels comply with all relevant regulations, including labeling requirements for hazardous materials, and other standards applying to your products.

Security Features

Consider features like tamper-evident labels, holograms, or digital watermarks to protect against counterfeiting and unauthorized tampering. Enhancing labels with RFID or NFC tags can add another layer of security with real-time tracking and ease and accuracy of inventory management.

Still Have Questions? We’ve Got Answers!

If you have questions about printing labels for the industrial and manufacturing industry, give us a call.