How Does UV Rotary Screen Printing Work for High-End Packaging?

UV rotary screen printing plays a unique role in the world of high-end packaging, offering both visual appeal and technical precision. Known for its ability to apply thick layers of ink with exact control, this printing method delivers vibrant color, raised textures, and striking design effects that stand out on the shelf.

It’s especially valued in luxury markets where tactile details and eye-catching finishes matter. Unlike traditional techniques, UV rotary screen printing pairs speed with sophistication, making it a reliable choice for large-scale label printing without sacrificing quality. From bold graphics to subtle textures, this process offers the tools to create a premium look and feel.

UV rotary screen printing plays a unique role in the world of high-end packaging, offering both visual appeal and technical precision. Known for its ability to apply thick layers of ink with exact control, this printing method delivers vibrant color, raised textures, and striking design effects that stand out on the shelf.

What is the UV Rotary Screen Printing Process?

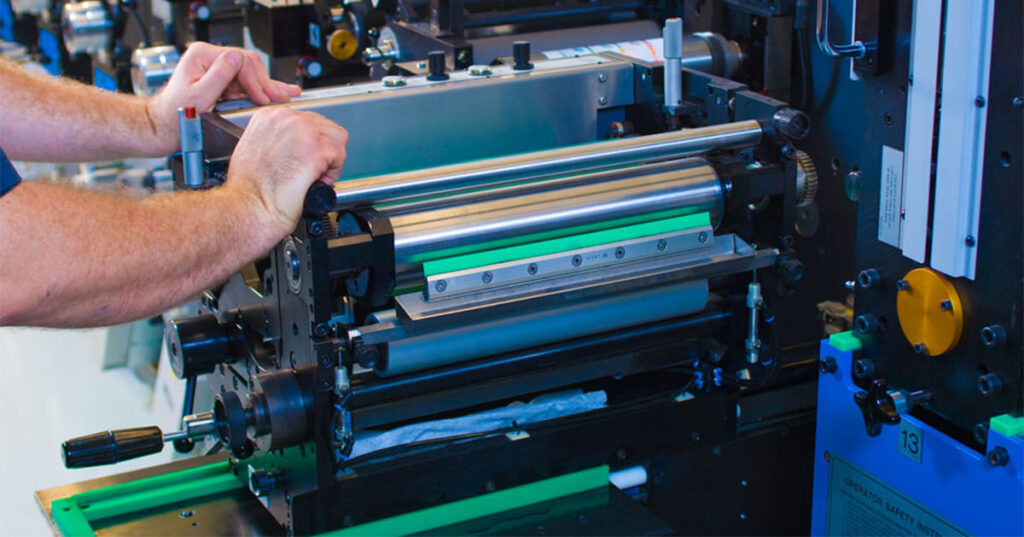

UV rotary screen printing is a high-quality label printing process that uses a cylindrical screen instead of a traditional flat one. Inside the cylinder there is a squeegee that transfers ink through the mesh on to the label substrate. As the cylinder rotates, the label substrate moves beneath it in sync, allowing for continuous and efficient ink application.

This setup provides greater consistency and speed than flat screen printing. UV-curable inks are used in this method; they dry instantly through polymerization when exposed to ultraviolet light. This quick curing process supports vibrant colors, raised textures, and intricate detailing without smudging or delay.

Ideal for high-end packaging, UV rotary screen printing offers precision and reliability while producing complex label designs on a large scale with excellent color depth and visual appeal.

What Makes UV Rotary Screen Printing Ideal for Luxury Labels and Packaging?

UV rotary screen printing is ideal for luxury labels and packaging because of its ability to apply heavy ink layers, creating rich color and striking visual depth. This method supports tactile and 3D effects like Braille, textured varnishes, and raised logos, features that elevate product presentation in high-end markets such as wine, cosmetics, and fragrance.

These effects not only draw attention but also create a sense of quality and craftsmanship. The process also allows for sophisticated finishes, including opaque whites, high-gloss accents, and the sought-after “no-label” look, where the design appears printed directly onto the container. These unique capabilities make UV rotary screen printing a top choice for brands seeking a premium, distinctive shelf presence.

What Specialty Effects Can Be Achieved with UV Rotary Screen Printing?

UV rotary screen printing unlocks a wide range of specialty effects that bring packaging to life. Brands can incorporate glitter pigments, halftone patterns, spume textures, thermochromic inks, and even security elements like hidden patterns or microtext.

These creative touches add depth and sensory interest while reinforcing product stories and brand identity. Thermochromic inks that react to temperature or textures that invite touch can build emotional connections with consumers. Security features help protect against counterfeiting, especially for premium products.

The method also allows exceptional flexibility in design, making it easier for brands to stand out in competitive retail spaces. With UV rotary screen printing, creativity isn’t limited. Instead, it’s a powerful tool for both function and visual impact.

Is There a Rotary Screen Printer Near Chicago?

For brands looking to create packaging that speaks to quality, creativity, and distinction, UV rotary screen printing offers a compelling solution. From vibrant inks to tactile effects and anti-counterfeit features, this method delivers both visual impact and production efficiency.

It’s particularly well-suited for industries where presentation carries weight, like wine, cosmetics, and fragrance. If you’re ready to explore how this process can elevate your next project, contact Gallas Label & Decal today to start the conversation.